Structural Integrity Engineering

Structural Integrity Engineering, Inc. (SIE), was formed in 1981 to provide engineering, project development and technical consulting services to the aerospace industry. SIE is headquartered in Chatsworth, California (30 miles north of Los Angeles) and also has a branch office in Madrid, Spain. SIE has a staff of 50 professionals consisting of certification engineers, aircraft designers and aircraft technicians. Five of the company’s engineers are FAA Designated Engineering Representatives (FAA DER) who have authority to approve reports and drawings for the FAA.

With the exception of the prime airframe OEM’s, SIE has performed more damage tolerance analysis for commercial aircraft than any other organization in the country.

History of SIE

1981

SIE founded

Damage Tolerance Analysis/Fatigue consulted

1986

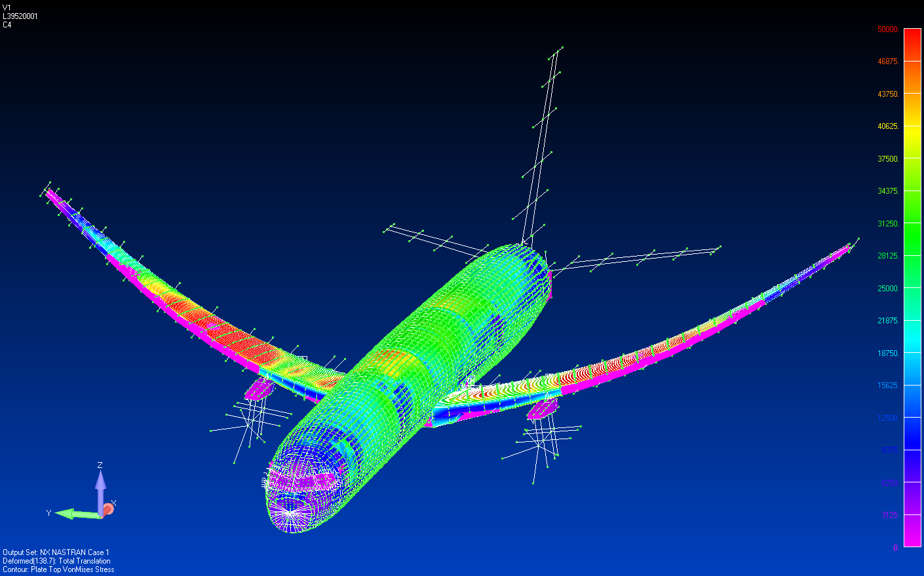

Stress Analysis and Finite Element Capability

1989

Structural Certification of DC-8 Hushkit

1991

Damage Tolerance (First DER)

1992

External Aerodynamic Loads, Operational Weight Upgrades for DC-8, B727

1995

STCs for Freighter Floors and Cargo Barriers

1996

Structural Design

1999

VIP Interiors

2002

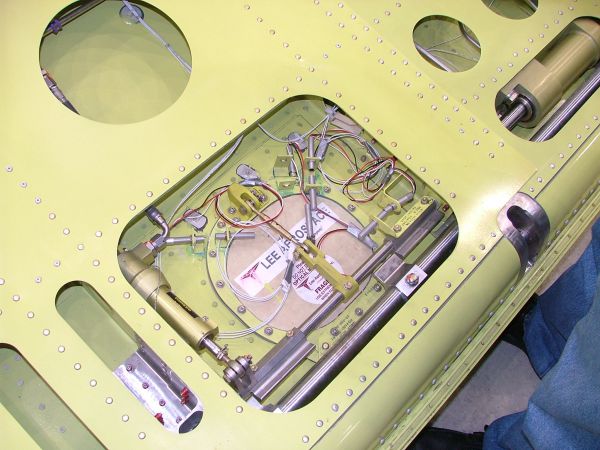

Systems Design and Certification (Electrical/Mechanical)

2003

Twin Otter Wing Life Extension STC

2006

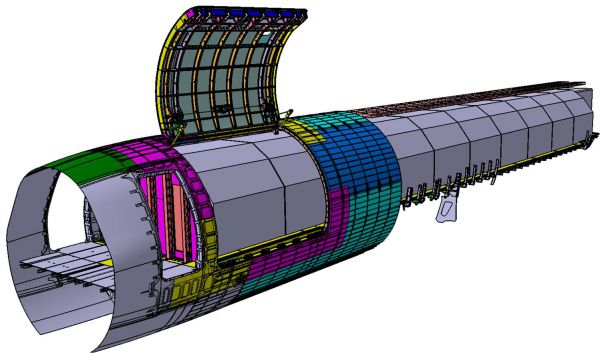

Design, Analysis, Certification, B757-200 Passenger to Freighter Conversion

2008

Pylon & Associated Systems for Honeywell Flying Test Bed Aircraft

2009

Procurement of Fabricated Parts & Components, Wifi and InFlight Entertainment Systems Installation & Design

2011

SIE Utilizes Additive Manufacturing for ECS Duct Modification

2012

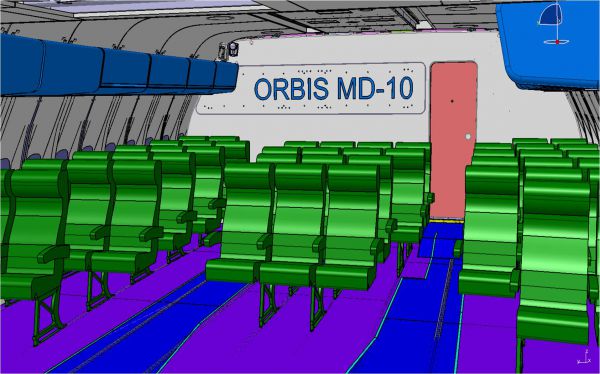

ORBIS Flying Eye Hospital

2014

AS9100 Certification

2015

Developed Test Pylon for GE Aviations’ Passport 20 Engine

2016

Started work on A320 Passenger to Freighter Conversion Program

2017

SIE Assists Honeywell in modification of its FTB