3D Printed Duct Analysis

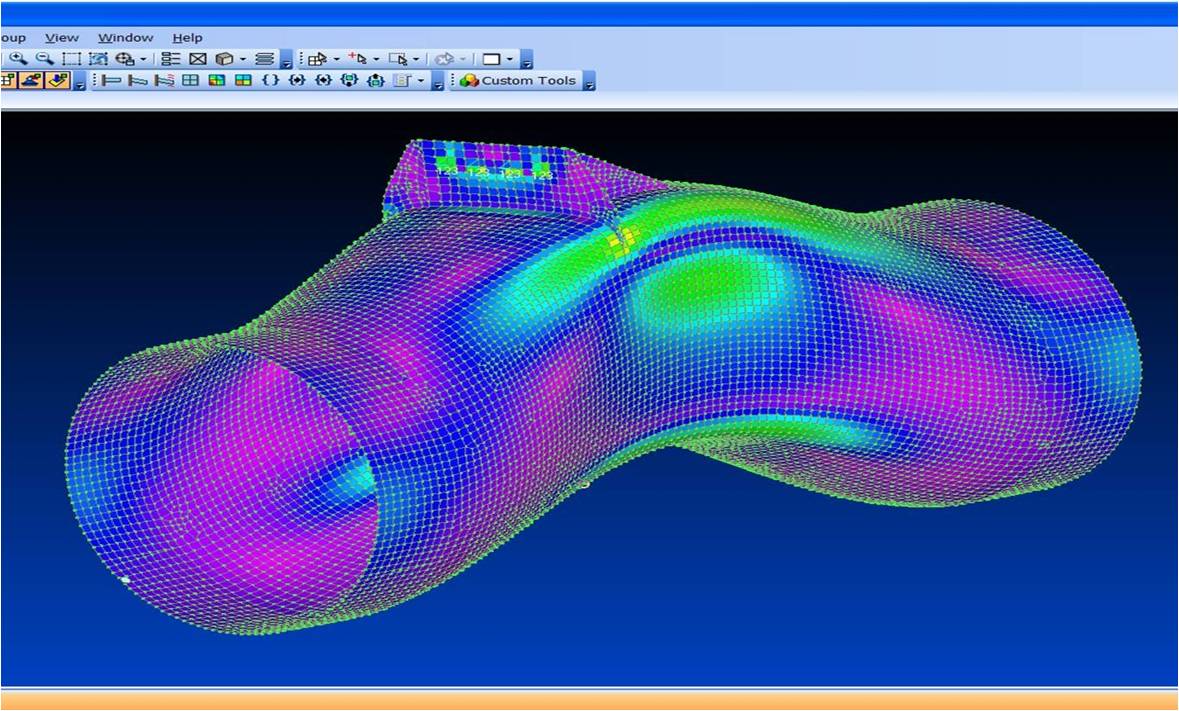

During the design of ORBIS' new MD10-30 FEH, SIE had to design a section of air ducting to transition up and over a rigid cargo barrier. The task was further complicated by the duct needing to morph in cross-sectional shape in order to clear other structural features associated with the barrier while maintaining its overall cross-sectional area.

3D Printed Duct

We chose to use a newly featured 3D printing compatible material brought to our attention by our vendor Solid Concepts. That material was smoke and burn compliant with FAA regulation FAR 25.853 and possessed sufficient strength to meet the FAA FAR requirements for pressurized ducts. During the design process, we were able to also reduce part count by integrating what would normally be separate mounting and strapping parts.